International Trade Sign Up

Sustainability

Lyngard Lighting

Our journey to net zero.

As designers and manufacturers, we take this very seriously. We have taken the first steps towards becoming a Net Zero Company.

Climate change is happening now

So what have we been doing behind the scenes to combat climate change?

"In order to know what we need to change, we need to understand what becoming net zero is all about. After being educated on this, we have been certified as carbon literate." — Carmen Lyngard

Carbon Literacy Project

We only have to look around us to see it happening, with an increase in floods and rising temperatures across the world.

But it’s not just that; we also have melting glaciers, rising sea levels, and shifts in plant and animal behaviors.

Changes in the carbon cycle have occurred due to human activities, especially post-Industrial Revolution, significantly disrupting the balance. Burning fossil fuels reintroduces old carbon into the atmosphere, and deforestation reduces CO2-absorbing trees while adding CO2 when trees are burned or decompose.

These actions reduce slow carbon sinks and increase atmospheric CO2, amplifying the greenhouse effect and driving climate change.

We will keep you updated on the changes we are making at the Lyngard factory based in the UK.

Powering our Lyngard factory in the UK

Onshore Wind Farms

Power for the factory and our kilns comes from electricity. The first step was to change how we are powered as a business.

We switched our supply to SSE Green Electricity.

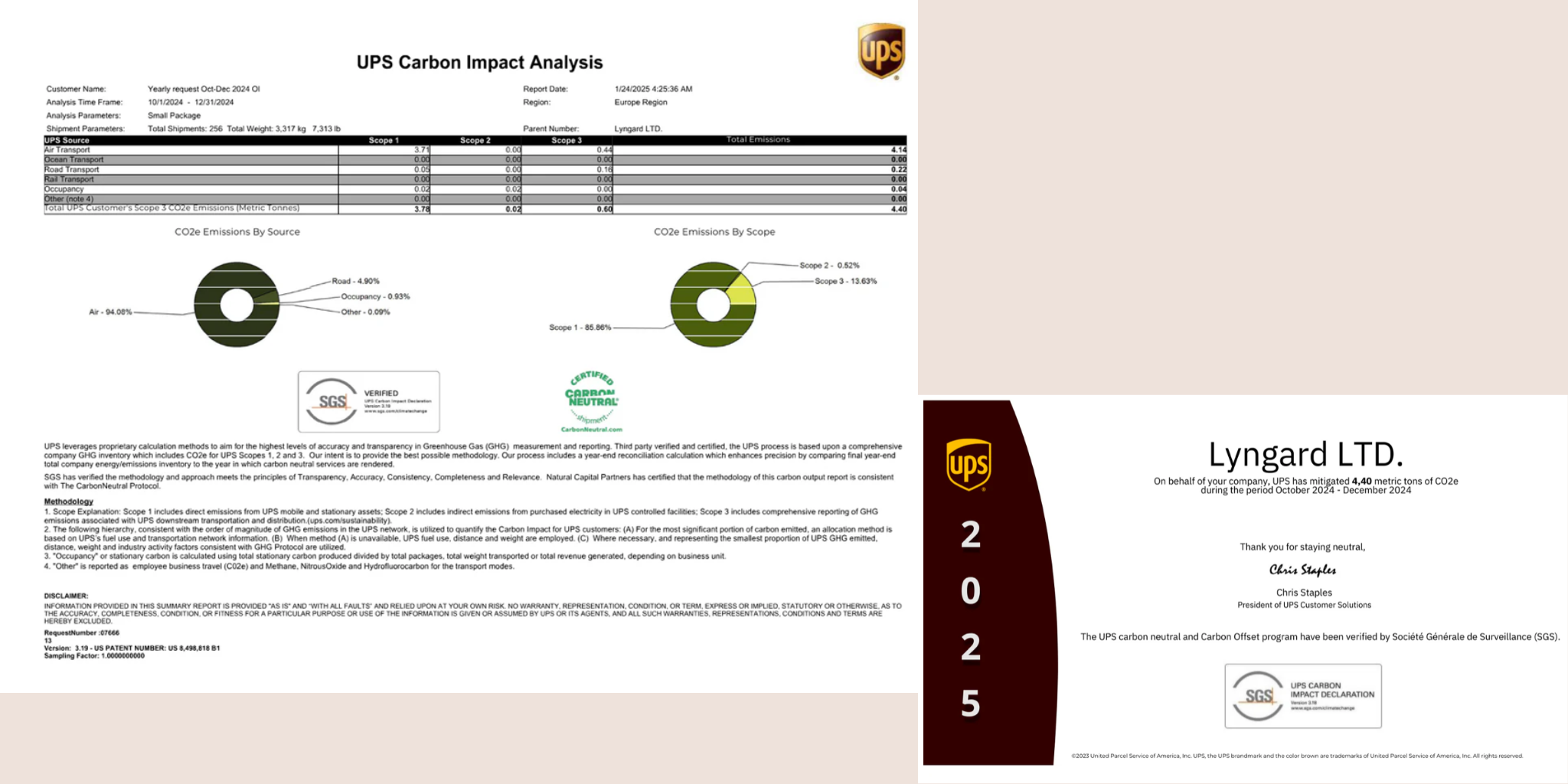

This means that, as of May 24, 2024, the Lyngard factory's power is 100% generated by wind and hydro assets, matched annually to Renewable Energy Guarantees of Origin (REGOs), enabling zero-emission reporting.

At Lyngard our journey towards sustainability is more than just a commitment, it's a driving force behind everything we do after becoming carbon literate.

Circularity of products

We recognize the importance of continually improving the manufacturing and design processes of our products. We are excited to share the steps we have taken and the processes we've made in embedding sustainability into the core of our operations.

STEP 1 : Embracing the Circular Economy

Our first major step was attending a circular economy course with the Lighting Association.This comprehensive training provided us with deep insights into the challenges we face in transitioning to a circular economy and the strategies to overcome them. The course was instrumental in helping us understand the importance of designing products that minimise waste, maximise resource efficiency, and extend product life cycles.

Step 2: Measuring our progress

With newfound knowledge, our next step was to measure how Lyngard products align with the circular economy principles.This involved a thorough evaluation of our manufacturing processes, product designs, and overall sustainability practises.Understanding our current ositionwas crucial in identifying areas for improvement and setting ambitious achievable goals.

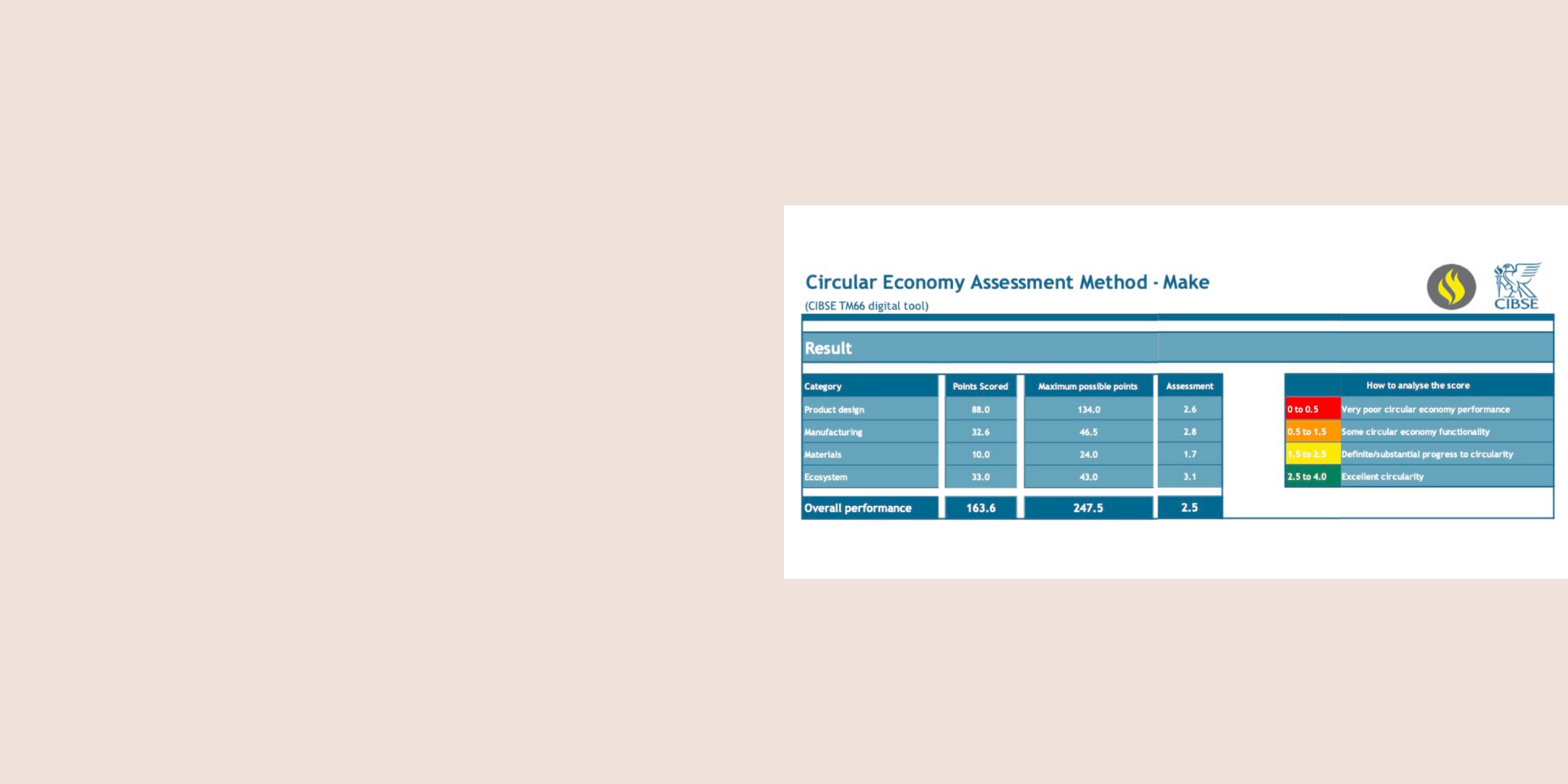

Step 3: Achieving TM66 certification

We are proud to announce that that our dedication to sustainable manufacturing has been recognised through the TM66 certification. This certification is a benchmark in the lighting industry, assessing the circularity of products or product groups. The focus is on the product longevity, ease of repair, and the ability to remanufacture parts. Achieving TM66 certification involved rigorous scrutiny of our products life cycle and their impact on the environment.

At Lyngard, we believe that sustainability is not just a goal but a continuous journey. Our TM66 certification score of 2.5, which classifies our products as having excellent circularity, is a testament to our efforts.

Our commitment to sustainability

This score reflects our commitment to producing high quality, durable products that stand the test of time and reduce environmental impact. We understand the importance of responsible consumption. and are committed to using recyclable packaging to minimise landfill waste, by ensuring our products are designed for longevity and recyclability, we are taking significant steps towards a more sustainable future.

At Lyngard every detail matters.

Our cardboard boxes are sourced responsibly and are of exceptional quality. We encourage our customers to reuse these sturdy boxes, which can be used repeatedly. They are FSC mix certified, assuring you that they come from responsible forestry.

At Lyngard lighting we are constantly striving to improve our packaging, ensuring it is both high-quality and environmentally responsible.

To protect our lights in transit, we use kraft paper made from 100% recycled post-consumer waste paper , sourced from an FSC approved provider. This paper is not only 100% recyclable but also compostable and biodegrable after use.

Additionally, the bubble wrap we use around the light shades is eco-friendly, made from 30% recycled content. We encourage our customers to reuse or recycle this bubble wrap.

The paper gummed tape used to secure your boxes is made from natural kraft paper and can be recycled along with the boxes and other paper-based packaging materials. Even our fragile tape is 100% recyclable.

At Lyngard lighting, we ensure our packaging reflects our dedication to sustainability and quality, helpingour customers acheive a greener more responsible lifestyle.

As we celebrate our 10th Anniversary we want to take this opportunity to share the backbone of success and our dedicated and close-knit supplier base. All proudly located withink the UK.

Supplier Base.

Over the past decade, these partnerships have enabled us to consistently deliver the highest quality products on the market, ensuring that every Lyngard creation eets stringent standards of excellence.

Our light shades are renowned for their durability and stunning translucency when lit, and this is largely due to the premium fine bone china clay we use.

Premium Fine Bone China Clay

This exceptional clay is sourced from naturally occurring minerals, crafted from the finest quality koalins and feldspars. This meticulous selection process guarantees that our shades not only look beautiful but are also built to last.

For our lighting components we collaborate with a local manufacturer who shares our commitment to quality and sustainability. Our solid brass components boast a buy in metal content that is 78% recycled.

Local Excellence in Lighting Components.

A figure we are proud of and they are committed to increasing this to 90% by 2030. This move is part of our broader mission to enhance the sustainability of our products while maintaining the superior craftsmanship our customers expect.

Being located in Staffordshire has been a tremendous advantage. This region's rich history in ceramics and manufacturing means we have access to a wealth of knowledge and an array of skilled suppliers.

The Rich Heritage of Staffordshire.

Our glaze supplier for instance, formulates glazes with a keen eye on environmental impact, using non toxic and eco friendly materials to ensure both beauty and sustainability.

Quality and safety are paramount in our operations, which is why our cable options are sourced from the best available suppliers from Northern Ireland.

Top quality cables from Northern Ireland.

These cables are certified UKCA, CE and UL approved for the US and Canadian markets, underscoring our commitment to meeting rigorous safety standards globally.

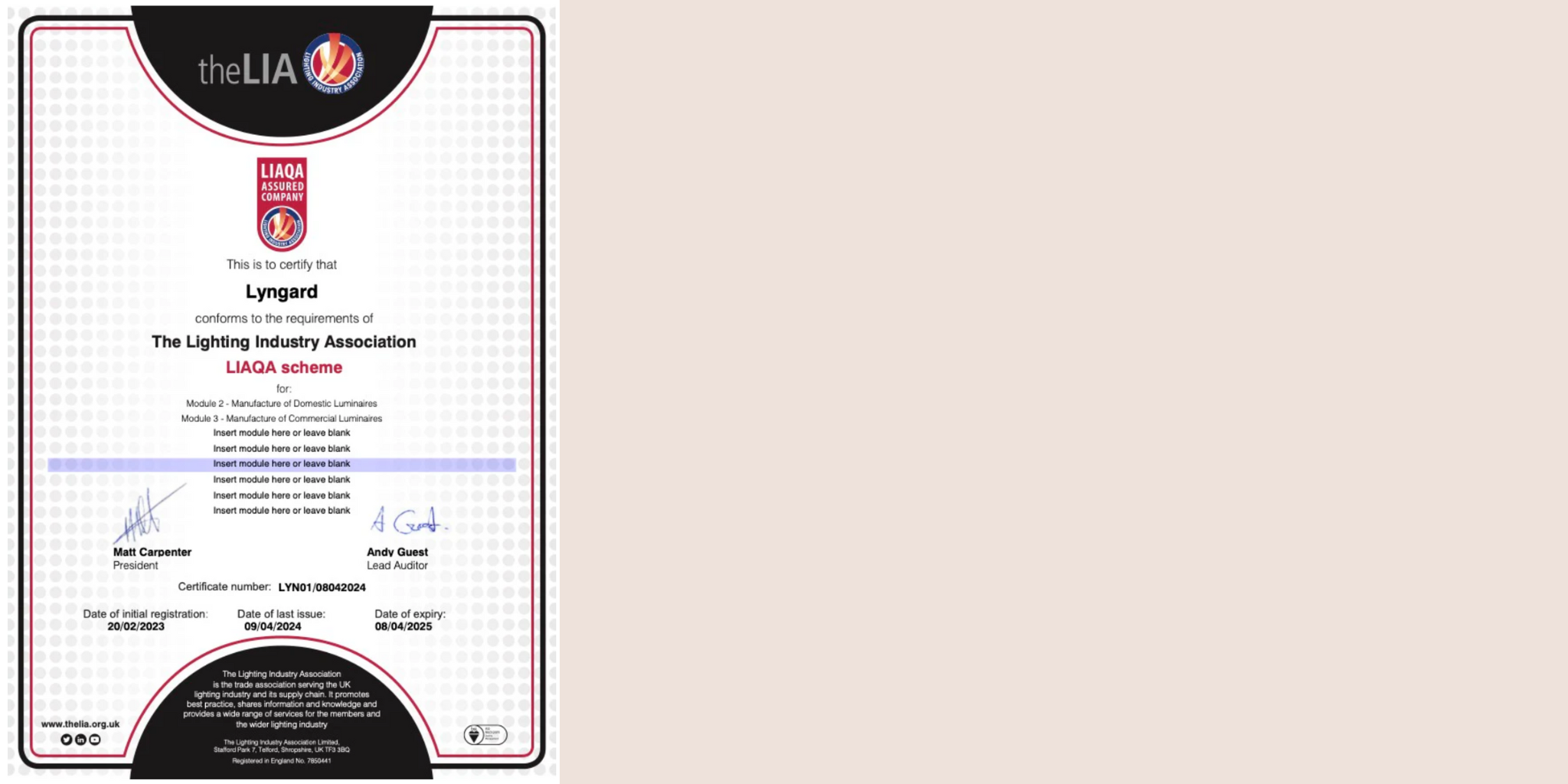

We are thrilled with our progress but know there is always more to do as we continue to innovate and improve. We remain dedicated to leading the way in sustainable manufacturing within the Lighting Industry. We are a quality assured LIA british company. Our journey is driven by a passion for creating products that not only illuminate but also protect our planet.

Looking ahead.

Thank you for being part of our journey. Together we can make a difference and pave the way for a brighter, more sustainable future. Warm regards, Carmen and Iain